TECHNICAL ARTICLE

Penetrant to improve water behaviour in non-wetting soil

What Causes Water Repellency?

A commonly held scientific view is that water repellency is caused by the accumulation of organic matter (slime) or rather non-polar organic coatings on the individual minerals that form the surface of the soil.

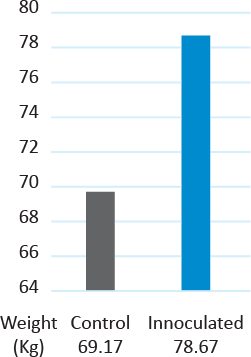

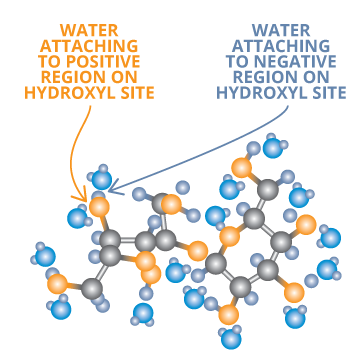

In essence, water molecules are polar, having a positive charge at one end and a negative at the other (Image 1). Water beads on dry “non-wetting” surfaces as these polar charges are attracted to each other more than the (non-polar) hydrophobic soil surface we are trying to wet.

Image 1

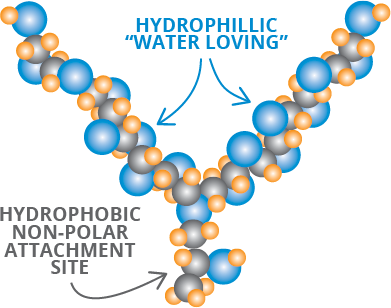

Wetting agents are long molecules with hydrophilic (water-loving) parts and hydrophobic (water-hating parts).

Image 2: Graphic representation of typical in-block co-polymer. Surfactant normally attaches to hydrophobic (water repellent) surface at its non-polar functional group site(s)

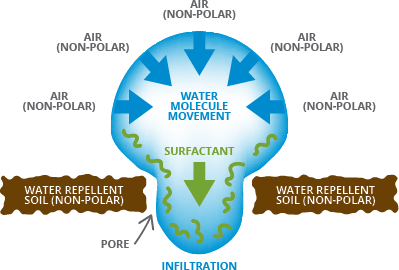

On the soil surface, these long molecule surfactants work by forcing their hydrophobic tails into the beads of water, reducing surface tension to create a wetting front along the surface of the soil.

Image 3

In this manner surfactant wetting agents enable water to “Penetrate” soil pores, however, water is enabled to leave easily too.

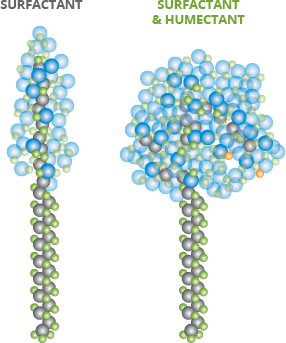

There are several strategies to prevent water from leaving too quickly. One is to shorten the life of the wetting agent, the second is to incorporate a retention capacity (Image 4). That is a compound that “Retains” water and nutrients such as a long-chain hydrocarbon molecule. This has a tail attractive to soil particle surfaces at one end and another tail attractive to water molecules and nutrient ions at the other end.

Image 4

Humectant polymers (Image 5) are useful having a hydrophilic nature, that is they are attracted to water, aiding capillary movement. Used in conjunction with Hydroscopic surfactants, which readily absorb moisture significant moisture retention and availability can be achieved. This presents a solution for both soils that repel water such as sands, and also soils that do not release water such as clays.

Image 5: Example of water molecules attaching to positive and negative regions of hydroxy groups on simple sugar humectant

Image 6: An example of rhizosheath activity around the plant root

A sophisticated band-aid has been detailed thus far, that for a prolonged period will create wetting conditions, where water can be held and freely transported to the plant.

The step forward is to use this relief valve opportunity created by using a sophisticated complex of surfactants and humectants in order to “Activate” natural soil processes that work continuously to reduce and prevent further non-wetting conditions from establishing.

“Activation” of biology occurs when plants begin to produce root exudates. Eco-Wet®s advanced formulation facilitates increased nutrient and moisture availability, thus resulting in increased productivity. A simple example of this can be seen in both the consistency of germination in conjunction with increased microbial rhizosphere activity. Evidence of this can be further measured by judging the extent of rhizosheath activity (Image 6), that is the dreadlock effect seen on plant roots when active exudates are being produced attracting increased microbial activity. This is the very beginning of soil structure and longer-term soil improvement.

Key modes of action

Penetrant:

Eco-Wet® utilises both fast-acting and controlled-release surfactant technology containing polar and non-polar properties to facilitate the initial rapid ‘breaking’ of repellency, whilst also maintaining improved availability and consistent distribution of soil moisture during the growing season.

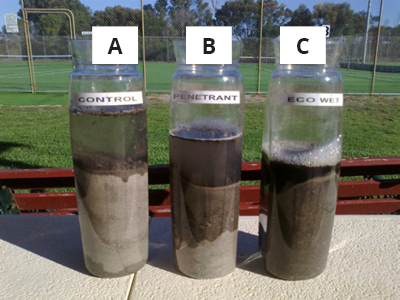

Image 7

A = Untreated

B = Penetrant only

C = Eco-Wet® Penetrant & retainer

Image 8: Example of increased microbial activity associated with increased root exudates and resulting “Dreadlock” rhizosheath effect.

Retainer:

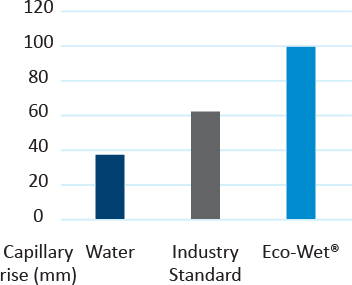

Importantly, Eco-Wet® also contains a polymer humectant retainer that exhibits significant capillary action, which promotes the ‘wicking’ of water (via capillary action) to the treated area – further increasing overall moisture levels in the greater soil profile.

Capillary rise in non-wetting sand over 10min interval

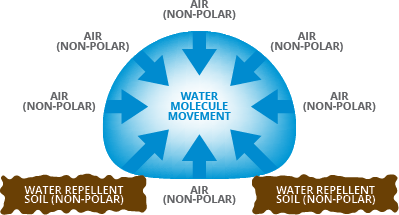

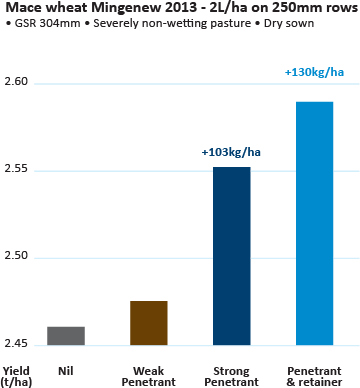

Industry trials have definitively demonstrated the value of a combined Penetrant and Retainer

Source: Dr. Paul Blackwell (DAFWA)

Activator:

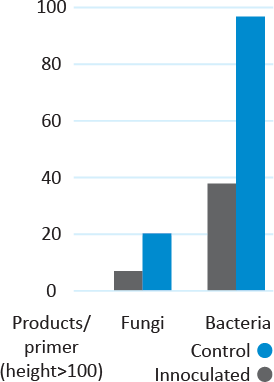

Increased moisture availability + Cation Exchange of nutrients + Microbial stimulation (Image 8).

Average dry-washed root weight

DNA extractable fungi & bacteria from plant rhizosphere

Delivery

Apply via a continuous stream of liquid to the surface well behind the press wheel and/or in a furrow close to the seed as possible.

- Use a minimum of 50L/ha of final solution.

- Higher volumes of water will achieve the best response.

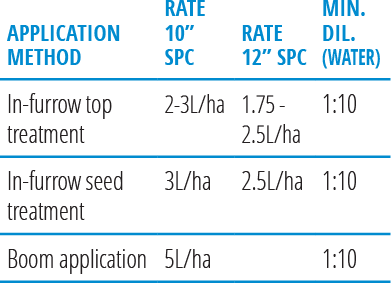

Eco-Wet® Application rates

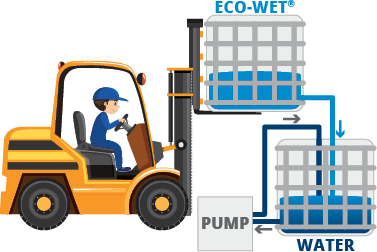

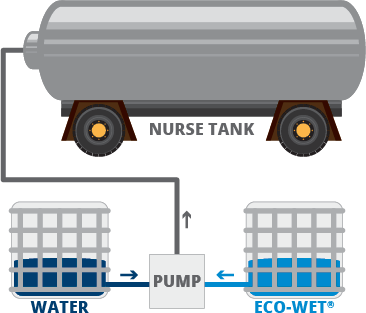

Pre-dilution of Eco-Wet®

- Fill IBC with 500L of water

- Gently agitate water whilst gravity feeding Eco-Wet® to water in IBC

- Avoid splashing solution by returning recirculated solution below the 500L mark

Recommended mixing procedure prior to pumping into nurse tank

- Half-fill liquid cart tank with water and/or compatible fertiliser

- Pre-dilute Eco-Wet® 1:1 with water whilst gently agitating.

- Gently agitate the liquid cart whilst adding Pre-diluted Eco-Wet®

- Add compatible nutrition

- Bring up to volume with remaining water / compatible fertiliser

20L Water + 30L Compatible Nitrogen + 3L Eco-Wet® Mixture is stable for up to two hours without agitation, however minimal agitation is required to regain homogeneity.

Example compatibility with Nitrogen

20Lt of water + 7Lt Eco-Wet® + 30L Nitrogen compatible at tested range of 15-35°C

Additional Nutrition may also be applied with Eco-Wet® subject to compatibility with a total solution.

Physical compatibility test procedure

- In a screw-top jar add 500mL of water.

- Add Eco-Wet® i.e. for 2L/ha application rate add 20 millilitres.

- Cap the jar and shake it well.

- Add additional products ie Express® Trace, 5L/ha rate add 50 millilitres.

- Cap the jar and shake it well.

- Let the jar stand undisturbed for at least two hours, but preferably overnight.

- Look for any obvious incompatibility such as flocculation or precipitation. Some settling of flowable or powder products is normal. But if you have difficulty in re-suspending sediment then extra agitation during spraying is needed or it may cause blockages and uneven application rates.

- Dispose of the jar and its contents safely after this test.

Note, that tested ingredients should be added in order of least solubility first, some products may require pre-dilution before adding to the jar as per normal practice.

Related products

Eco-Vital®

A premium natural kelp and fish fertiliser with plant extracts that delivers rapid results.